Dhananjay Bioenergy Pvt. Ltd. is a new venture of the Dhananjay Group, established with a vision to transform agricultural and forest waste into valuable renewable energy resources.

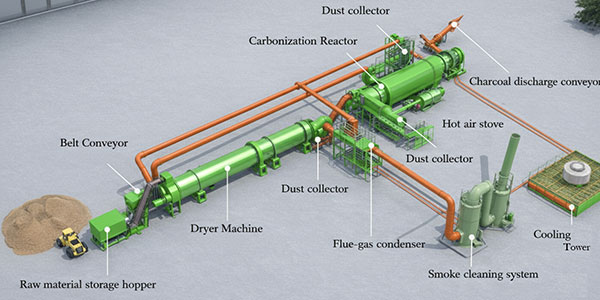

We provide end-to-end engineered solutions for biomass processing from raw material size reduction to drying and carbonization.

Backed by strategic technology joint ventures with internationally established companies, we combine engineering excellence, robust manufacturing infrastructure, and decades of industry expertise to provide reliable, high-performance, and sustainable biomass processing systems.

Continuous Carbonization Process

KEY PLANT SPECIFICATIONS

Design, manufacturing, and erection of the 1 TPH Continuous Carbonization System with rotary dryer including complete engineering, fabrication, and on-site installation, as per the specifications given below.

| Sr. No | Parameter | Details |

|---|---|---|

| 1 | Biomass | Bamboo Chips (5-30 mm) |

| 2 | Moisture Content | 30% |

| 3 | Feeding System | Weighing Scale at Biomass Feeding System |

| 4 | Rotary Dryer Input Capacity | 1.25 Ton Per Hour |

| 5 | Carbonization Furnace Input Capacity | 1.0 TPH with temperature monitoring at all levels |

| 6 | Condensation System | Two Condensers with Separation System for Bio-Oil & Wood Vinegar |

| 7 | Output Products | Biochar: 25–30% (Fixed Carbon: 75%) Bio-Oil: 15–20% Wood Vinegar: 15–25% |

| 8 | Automation | Fully Automatic with PLC System |

| 9 | Initial Heating Source | LPG |

Smart Automation for Biomass Processing Plants

At Dhananjay Bioenergy Pvt. Ltd., we integrate advanced PLC-based automation systems to ensure precise, efficient and reliable operation of biomass processing equipment.

Our PLC Intelligent Control System is designed to seamlessly monitor and manage every stage of the biomass process from feeding and chipping to drying and carbonization ensuring optimized performance and consistent output quality.