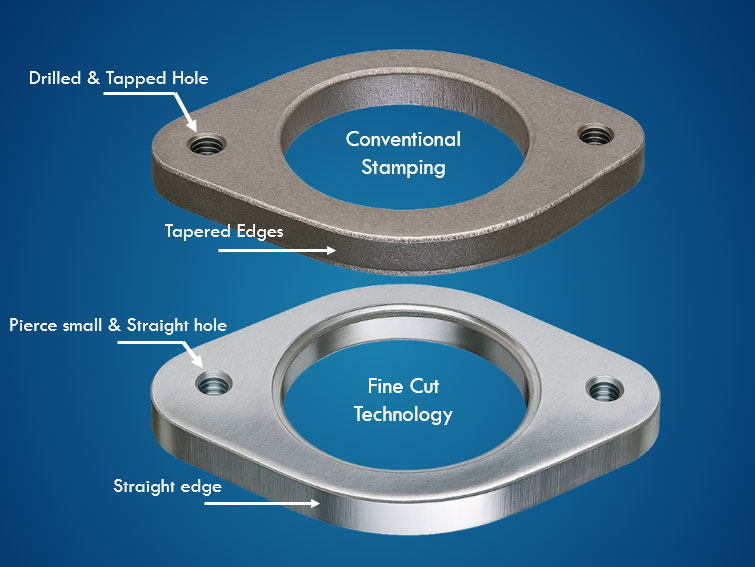

At Dhananjay Group, we specialize in Fine Cut Technology — an advanced sheet metal cutting process that bridges the gap between Conventional Stamping and Fine Blanking.

This innovative technology provides high-precision results at an economical cost, making it the preferred choice for automotive and industrial applications that demand accuracy, consistency, and cost efficiency.

Dhananjay Group continues to invest in advanced technologies like Fine Cut to deliver next-generation sheet metal solutions that meet the evolving needs of global customers.

Fine Cut Technology provides a superior finish, higher accuracy, and cost advantages — redefining efficiency in metal cutting and stamping.

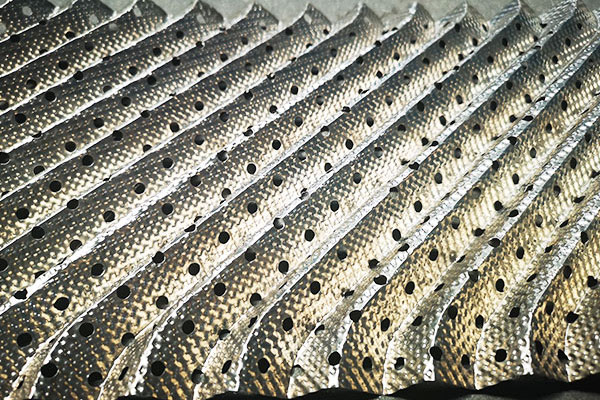

At Dhananjay Group, our state-of-the-art Stamping Facility is equipped with a comprehensive range of presses designed to meet the diverse requirements of our customers. With advanced machinery and intelligent automation systems, we ensure precision, consistency, and high productivity across all stamping operations.

Our facility is capable of handling both progressive and single-action tooling, supported by stringent quality checks at every stage. From prototype development to high-volume production, we maintain tight dimensional control, superior surface finish, and optimized material utilization, ensuring every component meets international standards of performance and reliability.

The Full Width Coil Auto Blanking Line at Dhananjay Group is engineered for high-efficiency, precision-driven sheet metal processing, enabling the seamless transformation of metal coils into flat blanks with exceptional dimensional accuracy and repeatability.

This fully automated line is capable of handling heavy-gauge coils up to 6mm thickness and 1300mm width, supporting a wide range of materials and applications across diverse industrial sectors. The integrated automation system ensures continuous coil feeding, precision leveling, and synchronized blanking operations, significantly reducing manual intervention and downtime.

By minimizing material wastage and ensuring uniform flatness and edge quality, the line delivers consistent, ready-to-form blanks that enhance productivity in downstream operations such as stamping, forming, and welding.

At Dhananjay Group, precision begins with cutting-edge technology. Our Fiber Laser Cutting Facility is equipped with an advanced 12 KW Trumpf TruFiber source, delivering exceptional accuracy, superior edge quality, and consistent performance across a wide range of materials and thicknesses.

With an expansive bed size of 6.5 x 2.5 meters, the system offers the capability to process both small precision components and large structural parts with equal efficiency. This flexibility allows us to cater to diverse industrial requirements, from automotive and engineering applications to heavy fabrication projects.

The high-power laser ensures fast cutting speeds with minimal thermal distortion, enabling clean, burr-free edges and reduced post-processing. Integrated automation for sheet loading, unloading, and nesting optimization enhances throughput while minimizing material wastage.

At Dhananjay Group, we offer advanced welding and fabrication capabilities to deliver high-quality, precision assemblies that meet stringent customer requirements. Our Welding & Assembly Division is equipped with both Robotic and Manual Welding Systems, ensuring consistency, efficiency, and flexibility across diverse applications.

Our dedicated robotic welding shop is equipped with 14 state-of-the-art robotic cells, designed for high-volume, repetitive, and complex welding operations.

At Dhananjay Group, our in-house machining facility stands as a cornerstone of precision and reliability. Equipped with state-of-the-art CNC and VMC machines, we ensure exceptional dimensional accuracy, consistency, and superior surface finish across all critical components — meeting the demanding standards of modern manufacturing.

This high-performance setup enables us to seamlessly execute complex machining operations on both standalone components and integrated sheet metal parts. By maintaining full control over the machining process, we ensure faster turnaround times, reduced dependency on external vendors, and uncompromised quality at every stage of production.

Our machining facility plays a crucial role in supporting the production of child parts used in our sheet metal assemblies, along with secondary machining operations such as drilling, tapping, milling, and contouring on formed sheet components.

Fully Automatic Alkaline & Acid Zinc Plating Plant: Our automated facility delivers uniform zinc coating with excellent adhesion and corrosion resistance. Supporting both alkaline and acid processes, it ensures precision, consistency, and efficiency for high-volume and specialized applications.

Manual Duplex Nickel Chrome Plating Plant: Our dedicated facility provides durable, high-quality duplex nickel chrome finishes with superior corrosion resistance and aesthetic appeal — ideal for specialized and high-performance components.

Fully Automatic Powder Coating Plant: Our high-capacity automated powder coating facility delivers durable, uniform, and eco-friendly finishes. Designed for efficiency and consistency, it ensures excellent coverage and surface protection for large-scale production.

Liquid Nitriding: Our advanced nitriding process enhances surface hardness, wear resistance, and fatigue strength while maintaining dimensional accuracy — ideal for improving component performance and durability.